- January 27, 2024

Revolutionize Your Industrial Hose Management with Innovative Hose Hanger Solutions

Kind Reader, have you ever felt frustrated with hoses cluttering up your workspace? If you work in an industrial setting, chances are you’ve experienced the hassle of tangled hoses and messy storage areas. Fortunately, there is a solution to this problem: the industrial hose hanger. This handy device allows for easy organization and storage of hoses, keeping them off the ground and out of the way. With an industrial hose hanger, you can increase efficiency and safety in your work environment while also reducing frustration and clutter.

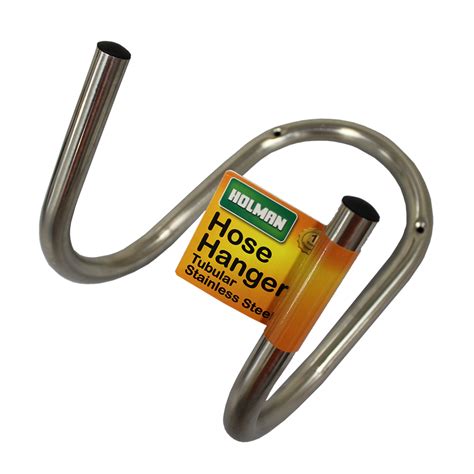

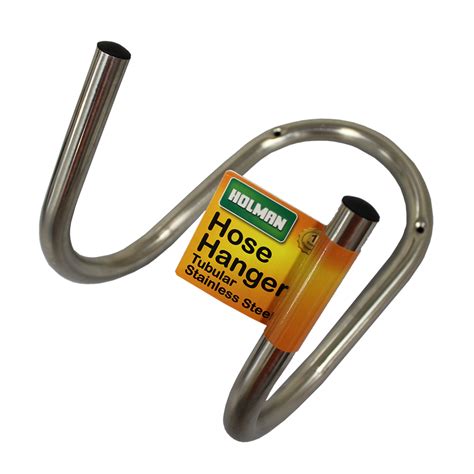

What is an industrial hose hanger?

An industrial hose hanger is a device used to store and organize hoses in industrial settings such as factories, construction sites, and workshops. These hangers come in different shapes and sizes, from wall-mounted brackets to portable floor stands, and can hold a variety of hose types, including air hoses, water hoses, and hydraulic hoses. Hose hangers are essential in preventing tangling, kinking, and damage to the hoses that can compromise their functionality and longevity.

The importance of hose hangers in industrial environments

Hose hangers play a crucial role in maintaining a safe and efficient workplace in industrial environments. Proper storage and organization of hoses not only prevent accidents and injuries but also saves time and increases productivity. Hoses that are left on the ground or piled up haphazardly are prone to damage and can cause trips and falls that can lead to serious injuries. By using hose hangers, hoses are kept out of the way, reducing the risk of accidents and improving overall workplace safety.

The different types of industrial hose hangers

There are several types of industrial hose hangers to choose from, depending on your specific needs and requirements. Here are some of the most common types of hose hangers:

| No | Type | Description | Pros | Cons |

|---|---|---|---|---|

| 1 | Wall-Mounted Hose Reels | Mounted on a wall, usually made of metal and offers better stability. | Easy to install; provides better organization and storage capability. | May be out of the way, which could make it difficult to access the hose. |

| 2 | Portable Hose Carts | Made of plastic or metal and easy to move around. Can also be used for storage. | Easy to move the hose around; offers flexibility in hose storage. | May only have limited storage capacity, and the hose may still be exposed to elements. |

| 3 | Hose Hangers or Stand | Usually, a simple stand that just hangs it in the open space. | Simple and cheap to use. | May be unstable, which increases the risk of hose damage. |

Materials Used in Industrial Hose Hanger

Industrial hose hangers are made from various materials. The type of material used will depend on the application, environment, and potential risks associated with the hanger. Here are some of the materials commonly used to manufacture industrial hose hangers:

Metallic Materials

Metallic materials like steel, stainless steel, and aluminum are popular for industrial hose hangers as they are durable and long-lasting. They can handle heavy loads and resist corrosion. Stainless steel hangers are used in harsh environments where there is a risk of rust and corrosion.

Plastic Materials

Plastic materials like Polypropylene and Polyethylene are used in applications where weight and flexibility are required. They offer excellent chemical resistance for use in corrosive environments and are often used in chemical plants or laboratories.

Rubber Materials

Hose hangers made from rubber are suitable for use in applications requiring a high level of flexibility and resistance to abrasion. They offer good resistance to extreme temperatures and are generally long-lasting. They are frequently used in the chemical and petrochemical industries and for firefighting purposes.

Types of Industrial Hose Hangers

Industrial hose hangers come in a variety of shapes, sizes, and styles. Manufacturers design them to meet the different requirements of industrial applications. Here are some of the common types of industrial hose hangers:

Wall-Mounted Hose Hanger

The wall-mounted hose hanger is attached to a wall, rack, or any other vertical surface. These types of hangers are used in applications where hoses are used frequently, and a specific location for the hose is necessary. They come in different sizes depending on the size of the hose.

Portable Hose Hanger

The portable hose hanger is designed to be moved around and is lightweight. They are best suited for applications where the hose needs to be moved from one location to another frequently. They are made from a variety of materials, including metal, plastic, or rubber, depending on the application.

Retractable Hose Hanger

The retractable hose hanger is a device used to store hoses when they are not in use. They are designed to be mounted to a wall or ceiling and feature a spring-loaded reel that automatically recoils the hose back into the housing. They are ideal for applications where hoses need to be kept out of the way when not in use and are easy to retrieve when needed.

Floating Hose Hanger

The floating hose hanger is used in marine applications where hoses are used to transfer fluids from one location to another. These hangers are designed to float on the water’s surface and keep the hoses from sinking. They come in different sizes depending on the size of the hose.

| No | Information |

|---|---|

| 1 | Name of product |

| 2 | Type of product |

| 3 | Material(s) used |

| 4 | Size options available |

| 5 | Maximum weight capacity |

| 6 | Features and benefits |

| 7 | Usage/application |

| 8 | Manufacturer/brand |

| 9 | Price range (if possible) |

Types of Industrial Hose Hangers

Industrial hose hangers come in different types that serve various purposes and installation methods. Here are some of the most common types of industrial hose hangers:

Wall-Mount Hose Holder

The wall-mount hose holder is a type of hose hanger that is mounted on the wall with screws. It keeps the hose off the ground and protects it from damage. The wall-mount hose holder can be made of metal or plastic.

Freestanding Hose Hanger

The freestanding hose hanger is a type of hose hanger that stands on the ground and keeps the hose off the ground. It is usually made of metal or plastic and is easy to move around.

Ceiling-Mount Hose Hanger

The ceiling-mount hose hanger is a type of hose hanger that is mounted on the ceiling with screws. It keeps the hose off the ground and out of the way. The ceiling-mount hose hanger is usually made of metal.

Factors to Consider When Choosing an Industrial Hose Hanger

When choosing the right industrial hose hanger, several factors should be kept in mind to ensure optimal performance and longevity. Some of the most important factors are:

Material

The material of the industrial hose hanger must be carefully chosen to ensure it can withstand the environment and weather conditions it will be exposed to. Metal hose hangers are more durable than plastic ones but may be affected by rust and corrosion over time. Plastic hose hangers are weather-resistant and don’t corrode, but they are not as durable as metal ones.

Capacity

The capacity of the hose hanger is another important factor to consider when choosing the right one. It must be able to hold the length and weight of the hose it’s intended for. A hose hanger with insufficient capacity may result in the hose falling off, causing damage, or creating a tripping hazard.

Installation Method

The installation method of the hose hanger must be taken into account to ensure ease of installation and compatibility with the intended location. A wall-mount hose holder may not be suitable if there’s insufficient wall space, and a freestanding hose hanger may be unsuitable if there’s limited floor space.

Factors to consider when choosing an industrial hose hanger

Choosing the right industrial hose hanger is imperative in ensuring safety and efficiency in your work environment. Here are some factors to consider when choosing the right industrial hose hanger:

1. Material

The type of material used in manufacturing the industrial hose hanger is important. The material should be able to resist corrosion, rust, and abrasion from the hose. Common materials used for hose hangers include stainless steel, aluminum, and PVC.

2. Size

The hose hanger should be designed to fit your hose size correctly. If the hose hanger is too small, it can cause damage to the hose, and if too big, the hose may not fit securely in the hanger. You should, therefore, check the measurements of the hanger to ensure it fits your hose correctly.

3. Type of hose

The type of hose you are using should be considered when choosing the right hanger. For instance, some hangers are designed for specific types of hoses such as suction and discharge hoses and pressure hoses. It is important to ensure that the hanger you choose is compatible with your hose.

4. Ease of installation

Choose a hose hanger that is easy to install and dismantle. You do not want to buy a hanger that requires special tools to install. The hanger should be easy to mount and dismount, making it easy to move it to other locations in your workspace.

5. Load capacity

Consider the weight of the hose when choosing an industrial hose hanger. A hanger with a lower weight capacity than the weight of your hose can lead to safety hazards such as slipping and damage to the hose.

6. Price

The cost of an industrial hose hanger varies depending on the type, material used, and size. Choose a hanger that fits your budget while ensuring it meets your industrial requirements.

7. Mounting options

An industrial hose hanger should have various mounting options for versatility in your workspace. Common mounting options include wall-mounted hangers, bench-mounted hangers, and ceiling-mounted hangers.

Choosing the right industrial hose hanger is important for safety, efficiency, and longevity of your hoses. Consider the material used, size, type of hose, ease of installation, load capacity, price and mounting options when choosing a hose hanger.

| No | Type of Hose | Ideal Hose Hanger |

|---|---|---|

| 1 | Suction and discharge hoses | Wall-mounted hangers |

| 2 | Pressure hoses | Ceiling-mounted hangers |

Types of Industrial Hose Hanger

Industrial hose hangers come in various types to match various needs. Among the types are:

1. Wall-mounted Hose Hanger

This type of industrial hose hanger is the most common. You affix the hanger to a wall or a flat surface, such as a pillar. The wall-mounted design makes this hanger perfect for storage because it does not take up floor space, and it is more convenient to reach when you need it. It’s convenient for tidying up the area or keeping the workspace organized.

2. Freestanding Hose Hanger

Unlike a wall-mounted type, freestanding industrial hose hanger stands alone without being installed to any surface. The design makes it mobile and capable of reaching a broader area and serves as the best solution for various work situations. In addition, it is a convenient option for those with less wall space to affix the hanger.

Apart from those two common types, there are several other industrial hose hanger designs, such as:

| No | Type | Description |

|---|---|---|

| 1 | Angle Bracket | A compact design with an angled hook with thin tabs for easy mounting using screws. |

| 2 | Double Arm | Double Sided, space-saving design made for easy pivotal movement in a limited area. |

| 3 | Slotted Design | A wall-mounted industrial hose hanger with a wide slot pattern that allows you to place the hanger at the desired distance. |

3. Hose Hanger Mounting Accessory

Mounting accessories are various types of brackets, clamps, and other mounting hardware that can give you more conveniences and options in your hose hanger installation for specific hose dimensions, weight, sizes, or types. In general, these accessories are optional; you don’t always need them unless you have special requirements. Talk to professionals before getting yourself a mounting accessory to make sure you have the right design.

Installation of Industrial Hose Hanger

Installing an industrial hose hanger might be a daunting task, but it is worth it for the efficiency and safety it provides. Here is a step-by-step guide on how to install an industrial hose hanger:

Step 1 – Choose the Right Location

The first step in installing an industrial hose hanger is to choose the right location. The ideal location should be easily accessible, dry, and secure. A concrete or wooden wall could be a great spot to install the hanger as it offers stability and strength.

Step 2 – Measure and Mark

Measure and mark the exact location where the hose hanger will be installed. Use a measuring tape and a marker for this step. Ensure that your markings are level and at a height that you can comfortably hang and detach the hose.

Step 3 – Drill Holes

Now it’s time to drill the holes into the wall using a drill and a suitable drill bit. The diameter of the drill bit must be smaller than that of the concrete wall anchors. Drill holes in the locations you marked earlier.

Step 4 – Attach Wall Anchors

Insert wall anchors into the holes using a hammer or an anchor gun. Make sure they are snugly fit into the holes. The wall anchors will provide the base and support for the industrial hose hanger.

Step 5 – Mount the Hose Hanger

Mount the industrial hose hanger on the wall anchors using the screws that came with the package. Tighten it enough to support the weight of the hose and ensure it is level.

Step 6 – Test and Load

Once you’re done with the installation, test the industrial hose hanger’s strength by hanging the hose on it before loading the hose. If everything is sturdy, you can now load the hose on the hanger, and you’re good to go!

Materials Used in Industrial Hose Hanger

Industrial hose hangers are made from a wide range of materials, including metals, plastics, composites, and wood. Each material has its own unique set of benefits and drawbacks. The choice of material for an industrial hose hanger largely depends on the application, environment, and budget of the user.

Metal Hose Hangers

Metal is a popular material for industrial hose hangers because of its strength, durability, and resistance to corrosion and damage. Common metals used for hose hangers include steel, stainless steel, aluminum, and brass. Steel and stainless steel are the most popular choices for heavy-duty applications, while aluminum and brass are better suited for lighter-duty applications.

Plastic Hose Hangers

Plastic hose hangers are lightweight, easy to install, and resistant to rust and corrosion. They are typically made from polypropylene, PVC, or nylon. These materials are affordable and easy to manufacture, making them a popular choice for industrial hose hangers.

Types of Industrial Hose Hanger

Industrial hose hangers are available in a variety of types and designs to accommodate different types and applications of hoses. Here are some of the most common types of industrial hose hangers.

Wall-Mounted Hose Hangers

Wall-mounted hose hangers are installed on a wall or any vertical surface that can hold the weight of the hanger and hose. They are designed to keep the hose off the ground and easily accessible. Wall-mounted hose hangers are available in different sizes and materials to support different hose sizes and weights.

Ceiling-Mounted Hose Hangers

Ceiling-mounted hose hangers are installed on a ceiling or any horizontal surface that can hold the weight of the hanger and hose. They are designed to keep the hose off the ground and easily accessible. Ceiling-mounted hose hangers are available in different sizes and materials to support different hose sizes and weights.

Industrial Hose Hanger FAQ

Get answers to your questions about the industrial hose hanger and discover how it can help address your concerns or anxiety about hose organization and management.

1. What is an industrial hose hanger?

An industrial hose hanger is a device that helps to organize and manage hoses in a factory setting. It is designed to keep hoses off the ground, making it easier to use and maintain them while preventing tangles and damage.

2. Is the industrial hose hanger easy to install?

Yes, the industrial hose hanger is easy to install. It comes with all the necessary components needed for installation, and it can be mounted on a wall or hung overhead to save floor space.

3. What types of hoses are compatible with the industrial hose hanger?

The industrial hose hanger is compatible with a variety of hoses, including air, water, hydraulic, and chemical hoses. It accommodates hoses of varying lengths and diameters and can be adjusted to fit your specific needs.

4. Does the industrial hose hanger come in different sizes?

Yes, the industrial hose hanger comes in different sizes to fit different types of hoses. It can accommodate hoses of varying lengths and diameters to maximize its usefulness.

5. Can the industrial hose hanger withstand heavy loads?

Yes, the industrial hose hanger is designed to withstand heavy loads and can hold up to several hundred pounds of weight. Its sturdy construction ensures that it can withstand harsh industrial environments.

6. Can the industrial hose hanger be used outdoors?

Yes, the industrial hose hanger can be used outdoors as long as it is protected from harsh weather conditions. Its durable construction ensures that it can withstand mild to moderate weather conditions.

7. Can the industrial hose hanger accommodate hoses with fittings?

Yes, the industrial hose hanger is designed to accommodate hoses with fittings. It has built-in hooks and loops that can hold hoses securely in place, ensuring that they do not come loose or get damaged.

8. How can the industrial hose hanger improve my workplace safety?

The industrial hose hanger can improve workplace safety by keeping hoses off the floor and preventing tripping hazards. It also ensures that hoses are stored in an organized manner, reducing the risk of accidents and injuries.

9. How does the industrial hose hanger help to prolong the life of hoses?

The industrial hose hanger helps to prolong the life of hoses by keeping them organized and off the ground. This prevents hoses from getting tangled or damaged, minimizing the need for costly repairs or replacements.

10. Does the industrial hose hanger require any maintenance?

No, the industrial hose hanger does not require any maintenance. It is made of durable materials that do not rust or corrode, ensuring that it remains in good condition for years to come.

11. Can the industrial hose hanger be customized?

Yes, the industrial hose hanger can be customized to fit your specific needs. It can be made to accommodate different types of hoses and can be painted to match your company’s colors.

12. How does the industrial hose hanger help to improve productivity?

The industrial hose hanger helps to improve productivity by making it easier to access and use hoses. It reduces the time and effort required to locate and retrieve hoses, allowing workers to focus on more important tasks.

13. Does the industrial hose hanger come with a warranty?

Yes, the industrial hose hanger comes with a warranty that covers defects in materials and workmanship. The length of the warranty varies depending on the manufacturer.

14. How can I ensure that the industrial hose hanger is installed correctly?

To ensure that the industrial hose hanger is installed correctly, it is best to follow the manufacturer’s installation instructions. You may also want to consult with a professional installer to ensure that the hanger is securely mounted and will not come loose.

15. How do I know what size industrial hose hanger I need?

You can determine the size of industrial hose hanger you need by measuring the length and diameter of your hoses. This will help you determine the appropriate size and capacity of the hanger you need.

16. Can the industrial hose hanger be used for other types of equipment?

Yes, the industrial hose hanger can be used for other types of equipment, such as pneumatic tools, power cords, and cables. Its versatile design makes it suitable for a wide range of equipment and materials.

17. How do I clean the industrial hose hanger?

You can clean the industrial hose hanger using a damp cloth or sponge. Avoid using harsh chemicals or abrasive materials that can damage the hanger’s surface.

18. How long does the industrial hose hanger last?

The industrial hose hanger can last for several years, depending on how it is used and maintained. Its durable construction ensures that it can withstand harsh industrial environments and remain in good condition for an extended period of time.

19. Can the industrial hose hanger be easily relocated?

Yes, the industrial hose hanger can be easily relocated. It can be mounted on a wall or hung overhead, allowing you to move it to different locations as needed.

20. Does the industrial hose hanger require any special tools for installation?

No, the industrial hose hanger does not require any special tools for installation. It comes with all the necessary components needed for installation, and it can be mounted using basic hand tools.

21. How can I order an industrial hose hanger?

You can order an industrial hose hanger online or through a local industrial supply store. Be sure to review product specifications and customer reviews before making a purchase.

22. What is the cost of an industrial hose hanger?

The cost of an industrial hose hanger varies depending on the size, capacity, and manufacturer. Prices typically range from $20 to $100.

23. How many hoses can the industrial hose hanger hold?

The industrial hose hanger can hold several hoses, depending on its size and capacity. It is designed to accommodate hoses of varying lengths and diameters, allowing you to store multiple hoses in a compact space.

24. How can I find the right industrial hose hanger for my needs?

You can find the right industrial hose hanger for your needs by considering the size, capacity, and compatibility with your hoses. You may want to consult with an industrial supply professional to ensure that you select the right hanger for your specific application.

25. Can I return the industrial hose hanger if I am not satisfied with it?

Yes, you can return the industrial hose hanger if you are not satisfied with it. Be sure to review the company’s return policy before making a purchase to ensure that you understand the terms and conditions of the sale.

If you are looking for a way to organize your industrial hoses, consider purchasing an industrial hose hanger. This will make it easy to access your hoses when you need them, while also keeping them neatly organized and out of the way when you don’t.

A Natural End to Our Journey

We have journeyed through the world of the industrial hose hanger, learning more about its uses and benefits. We hope that this article has provided you with the knowledge you need to make informed decisions about this essential piece of equipment. Thank you, Kind Reader, for accompanying us on this journey. We look forward to seeing you again soon, and we hope that our future articles will be just as helpful and entertaining as this one. Until then, take care and stay safe!